- #WHAT IS SOFTPIERCE PERCENTAGE IN SHEETCAM UPGRADE#

- #WHAT IS SOFTPIERCE PERCENTAGE IN SHEETCAM PRO#

- #WHAT IS SOFTPIERCE PERCENTAGE IN SHEETCAM SOFTWARE#

Quick Navigation General CNC Plasma / Oxy Fuel Cutting Machines Top You can make payment arrangements thru Well Made Manufacturing 60 for purchase. We purchased this system Apand funding went thru to Westcott Plasma April 26, 2018, if it is done and you pay us 70,000.00, we will pay off our note and you can pick it up directly from them and save yourself lots of time and aggravation. We had no choice but to purchase a different machine, purchasing this machine can save you the aggravation of demand letters, lawsuits, investigators and your local police departments time filing endless paperwork against Westcott Plasma. This machine was purchased last year, our major loss can save you lots of time and money, we have already waited 9 months and lost thousands of dollars waiting for the build, our business suffered losses after waiting past the 30 days of build time as promised. This Unit will be Brand New and currently at Westcott Plasma in Apache Junction, Arizona.

#WHAT IS SOFTPIERCE PERCENTAGE IN SHEETCAM PRO#

We are selling our Westcott Plasma 5'x10' Pro Series Plasma Table and Ultra Cut Plasma System, we have requested a refund from Westcott Plasma with no success only broken promises. I don't think you will find options to set or to change the plasma amps or air pressure and less likely from G-Code dynamically.

#WHAT IS SOFTPIERCE PERCENTAGE IN SHEETCAM SOFTWARE#

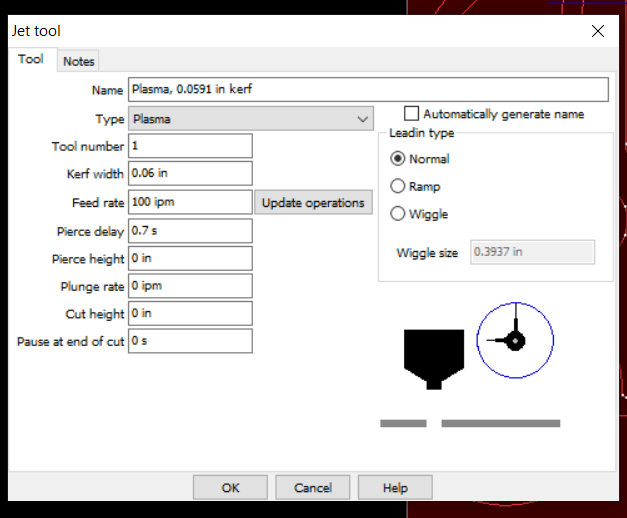

The control software has to have a way to dynamically insert changes in a way that is not based on macros that can cause motion delays.Ĭheck your INI setting options for WINCNC. The Hypertherm Powermax line (including the new 45XP) is the only products in the air plasma space that have the option to add a communications port to the unit and give you real time access to settings. In order to use SoftPierce you have to have remote software control over settings normally done manually: The current setting and the air pressure. By slowing down the process it allows piercing on thicker metal and puts less stress on the consumables Early testing shows a doubling of consumable life.The key to this is being able to change the cutting amps as its cutting. By starting the pierce at lower current (and even changing the air pressure) you reduce the shock on the consumables and lower the back-splash of molten metal (which limits the thickness of materiel an automated torch can do). N0130 ( Soft Pierce : 50 percent ) N0140 S900 N0150 M22 N0160 S3116 N0170 M22 N0180 S445 N0190 M22 N0200 S885 N0210 M22 N0220 M00 N0230(Check the DTHC Settings Hit RUN to continue) N0240 G00 Z0.5000 N0250 X1.4206 Y0.6680 N0260 G28.1 Z0.02 (Start Touch-Off ) N0270 G92 Z0.0 N0280 G00 Z0.1520 (Switch Offset Lift) N0290 G92 Z0. It lets you lower the pierce AMPS by a defined percentage and it automatically lowers the plunge rate for that pierce.

#WHAT IS SOFTPIERCE PERCENTAGE IN SHEETCAM UPGRADE#

N0130 (This code for use with Ether-Cut upgrade 12-19-14 or later) N0090 (DTHC has been disabled in this tool) N0080 (Operation: No Offset, Unnamed Level 1, T5: Fine Cut-Mild-Steel-16ga) N0020 (Post processor: DTHC-HYT-TAP_SoftPierce+Marker-rev11J.scpost) I'm still quite new at this but I thought the S379 code should override the hub and set Mach to 79V.Īnother odd anomaly I am having is sometimes the S10 does not turn off the DTHC at the start? As you can see in the screenshot taken after I ran the first section of the program posted below. It seems to be locked on the CandCNC hub setting. It does not like to load in the preset voltage setting.

0 kommentar(er)

0 kommentar(er)